Key Takeaways:

- 144-mile saved round-trip by switching to digital timesheets for just one crew

- 2 hours spent processing payroll instead of 2 days

- 3 days of data entry saved by digitizing construction logs

How many times have you wished for a tool more exacting than an excavator? A way to dig without worrying about hitting high-pressure gas lines or risking digging through electrical?

That’s why Ultra Engineering digs holes with air.

Ultra Engineering Contractors, Inc. uses air and vacuum technology to safely locate utilities so you can go back in with your excavator with confidence.

For years, Ultra managed projects with a single desk calendar and paper everything. Switching to Assignar saved them two days of manual data entry—just in time spent entering payroll.

Here’s how they use Assignar to streamline operations and manage projects throughout Southern California.

The old way: Meticulous paper systems suck up your time

Although nearly every process used paper, the Ultra team did their best to keep everything organized. The tradeoff was their teams’ time.

The Ultra team started with a desk calendar in 2014. They numbered their vehicles 1–13 and listed them out daily with all the pertinent information. This included:

- Client

- Project

- Assigned employees

- Tasks

- Extra equipment

- Start time

With all of this information, you can imagine how small the handwriting had to be.

In addition to the wall calendar, they used job tickets with carbon copies, wrote daily logs on legal pads, and used paper timesheets.

Gavin West, Ultra Engineering’s Controller, said the process worked when they only had five or six trucks to manage—but fell apart as they grew.

“Trying to fit in all the information—the client, the project, what two guys are going, if they need any extra equipment, their start time. And then aside from that, all of the extra information like the job tickets and timesheets also go along with it… obviously, it’s not enough space to make everything work,” West said. ““Now that we’re up to 13 potholing rigs plus the three or four locating rigs, it just became too much.”

With paper copies everywhere, the Ultra team struggled with their administrative tasks.

- Lost paperwork: The carbon copy job tickets were integral to the field process. Once the teams completed a job, they had to get sign-off from the clients. But according to West, keeping track of the paperwork was hard since the teams often worked new jobs daily.

“If they lose one or forget one, it’s gone,” West said. “They have just to make up a new one and hope the client will be available to sign it.”

- Trips to the office: With teams and vehicles all over Southern California and occasionally in other parts of the Southwest, dropping off this paperwork wasted time and money. One crew in San Diego had to spend 144 miles round trip weekly to drop off their job tickets, logs, and timesheets.

- Painstakingly slow processes: When the paperwork finally reached the office, the project manager still had to enter everything into the computer. For logs, this meant matching pictures from a digital camera with the corresponding day and job. It could take up to a week to enter them into the computer.

Running payroll was also a challenge. With timesheets delivered by Monday mornings and payroll due by Wednesdays, the administrative team struggled to enter the information into the computer in time.

It was clear that they needed a new solution.

“We needed to get everything online, in one central location,” West said.

The Solution: The power of the form

Ultra’s first step toward digitization was to find something to replace the paper calendar. Other products they looked at had Google and Microsoft calendar setups, which didn’t work for West.

“None of them had what we were looking for,” he said.

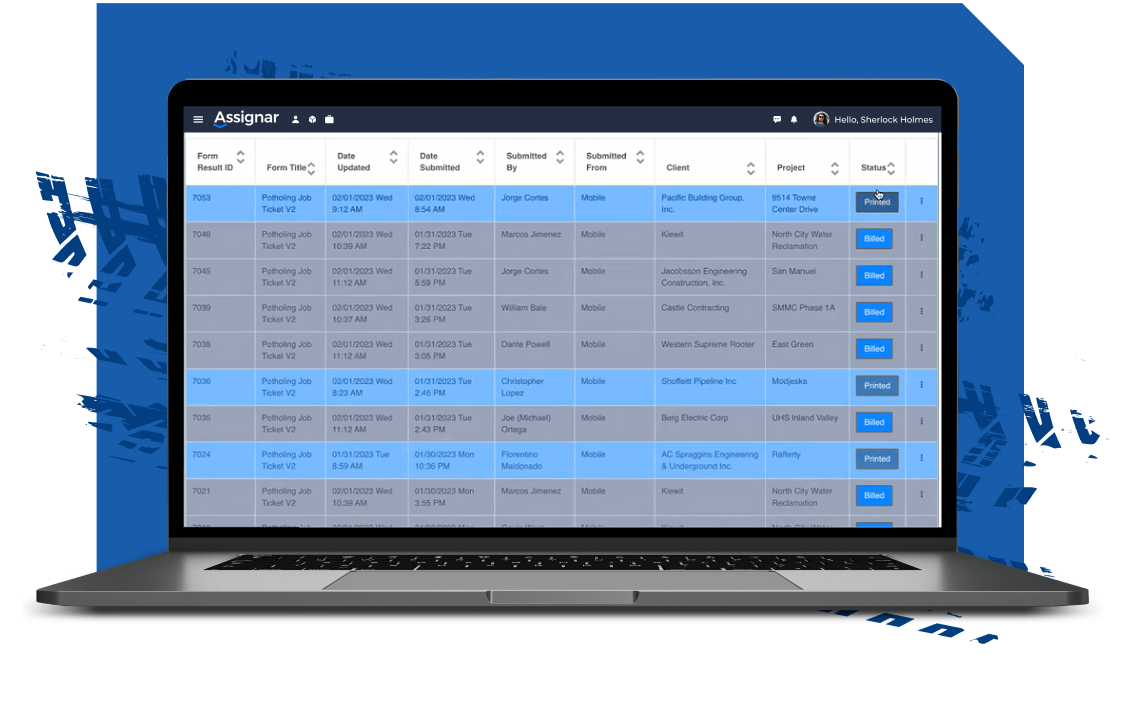

When he signed up for an Assignar demo, he still wasn’t quite sure if it was the right solution. But after an Assignar rep gave them a walk-through of the product, West could see that this was a product specifically built for construction. Even though West came for the resource scheduling feature, it was Assignar’s form feature that sold him.

“I started playing around with building the forms, and they have been a huge asset,” West said. “The guys type their info in on their phone or iPad, which auto-fills in the forms. The forms are customized, so everything looks like it was printed professionally and on our letterhead.”

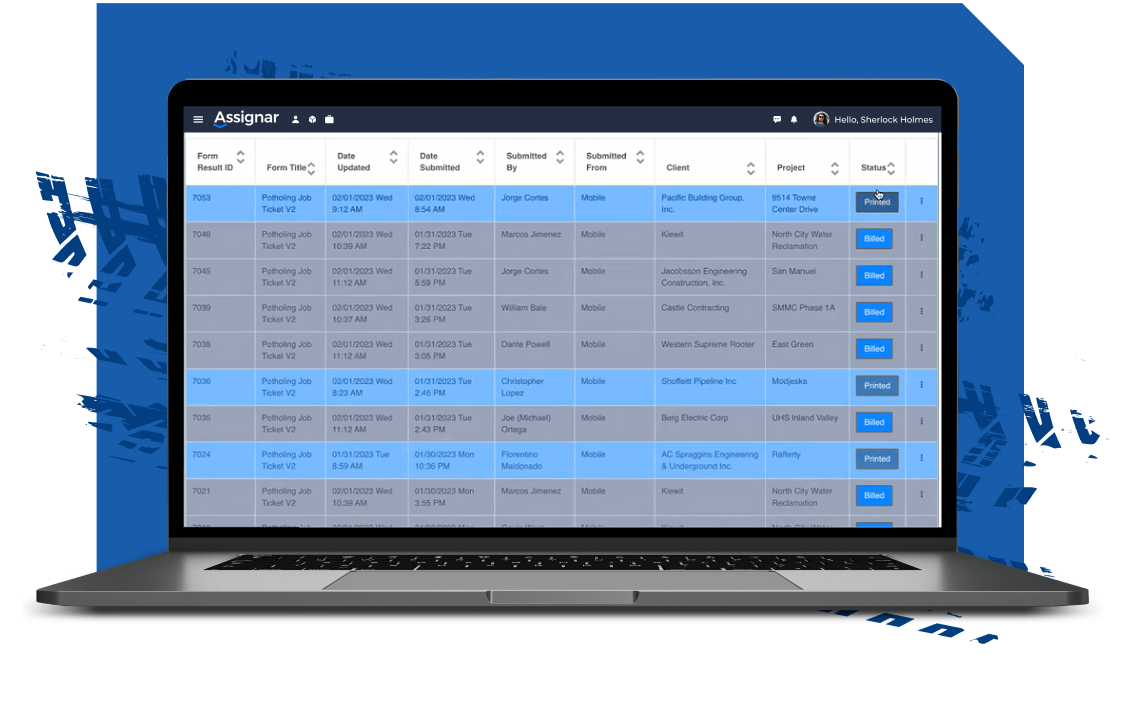

West now has all the forms he needs to run Ultra’s operations from Assignar. Boots-on-the-ground employees can fill out forms in the field, complete with dropdown menus to ensure they don’t forget any essential information. Plus, office staff gets the information as soon as it’s entered.

“Each week, we’re able to completely go through our books and make sure that everything that we’re done with is billed out for the week,” West said. “Having everything online and turned in on the same day has been a game changer for us.”

The Results: Saving time, miles, and money

West and the team embraced Assignar’s features and now run the majority of their operations through the platform. Going from paper to a centralized digital platform saved them days each week and has led to amazing results.

“Logging information with Assignar has helped us save a day or two a week, that can be used for literally anything else,” West said.

- Resource scheduling happens online: West and the Ultra team manage 13 vehicles and 23 employees from within Assignar, whether they have crews doing one job a day or on a year-long assignment.

- Paperwork doesn’t get lost: No more carbon copies and legal pads. Workers complete all job tickets and logs online using the Assignar app. They take pictures of the job site with their phones and iPads, and clients can sign off instantly.

- No manual data entry: When clients asked for logs, it used to take up to a week to enter, format, and double-check them manually. West said the process averaged two days, but it could have been a whole week’s worth of work on bigger projects.

“With Assignar, all of that’s just automatic,” West said.

Now, field workers complete logs directly in Assignar. When a client calls for the logs—rather than saying, “I’ll get back to you in a few days,”—the Ultra team can send them before they even hang up.

- Saving hundreds of miles a week: Crew members now complete timesheets in Assignar, and they don’t have to drive into the office weekly just to drop off papers.

On the administrative side, payroll is run by Monday at 11 am. It takes the team two hours instead of two days.

- Managing employee licenses and certifications: Ultra uses Assignar to stay on top of their employee certifications. Whether state qualifications like sexual harassment training or trade certifications, it’s all housed in the same easily accessible place.

Ultra also mandates that field workers have their insurance and registration with them at all times. Since these documents live in Assignar, employees can pull them up on their devices whenever necessary.

Optimizing vehicle maintenance

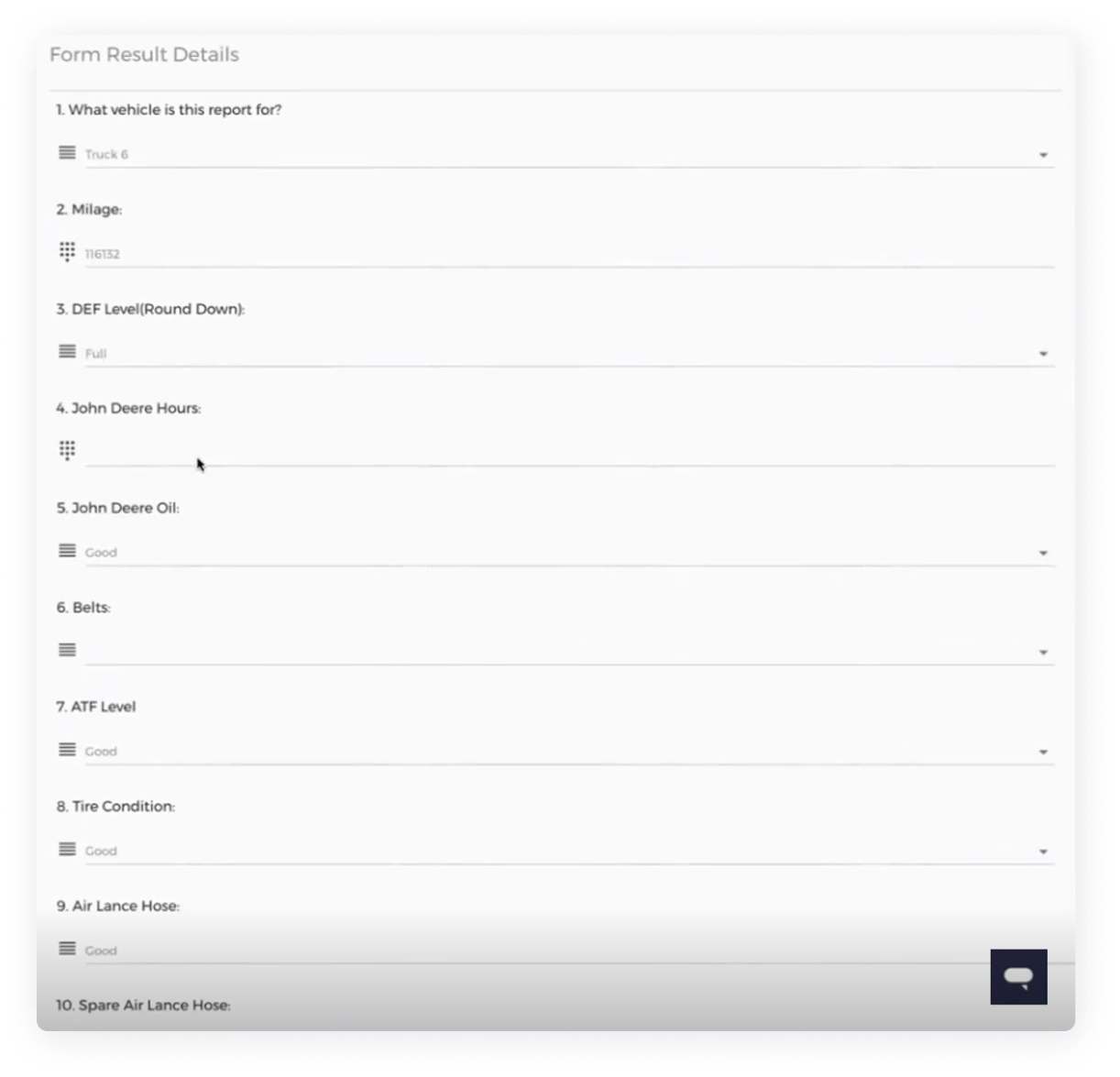

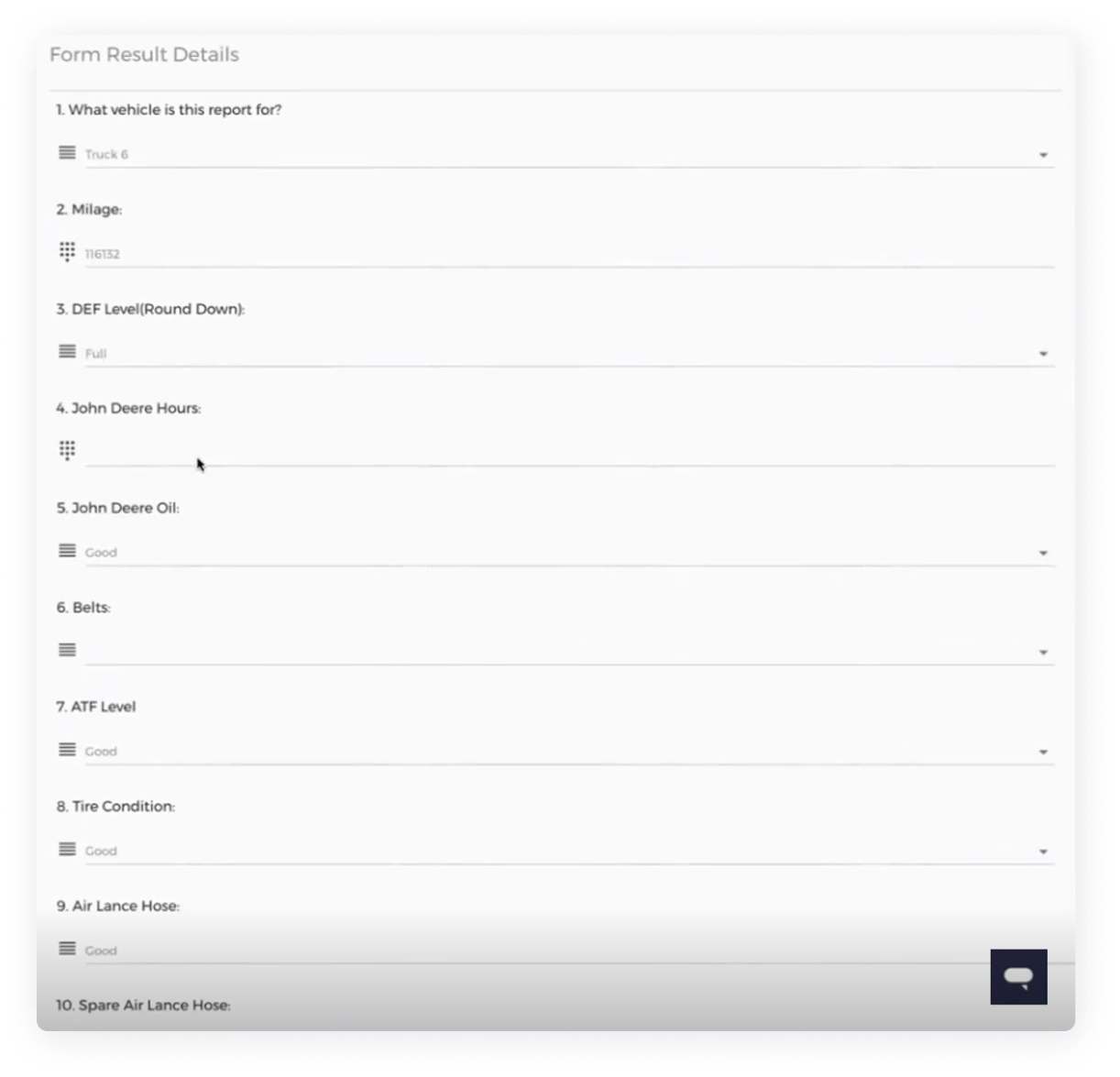

Ultra has also improved operations in ways they didn’t anticipate when they set out to find a digital solution. Now, they use Assignar to track vehicle maintenance, which is especially important since their trucks house their air/vacuum excavation equipment. Some of the details they record in their vehicle report forms are:

- Mileage

- Equipment in the vehicle

- Maintenance schedules

- Insurance

- Registration

West pulls up a form about Truck 6 for example: you can easily see mileage, DEF level, John Deere hours, John Deere oil, belts, ATF level, tire condition, light condition, and a complete rundown of all the gear that’s supposed to be on the truck such as air lance hoses, tamps, clay diggers, jack hammer, etc.—including spares!

There is also an open-text area where workers can write any problems they’ve experienced with the truck. It’s all logged in a central, easily accessible database with Assignar.

“If a truck needs maintenance, workers are able to turn in one of these forms and have it taken care of ahead of time. Rather than shooting someone a text and then have somebody drive out with the equipment,” West said. “This helps us stay proactive which saves us time in the long run.”

With the Assignar vehicle report forms, anyone on the Ultra office team can see at a glance what’s overdue or what maintenance they need to keep their vehicles in top condition.

Putting the pro in professional

The Assignar-powered Ultra improvements don’t stop there. Clients have taken notice of Ultra’s process changes.

“[Clients] are always impressed when, you know, the guys are doing all of their logs and reporting and everything on an iPad,” West said.

Ultra also now presents data in a professional and presentable format with just the click of a button. Using the custom printing feature, the team takes the raw data and images and builds a well-organized report.

Overall, Assignar has helped Ultra show off their professional prowess.

“Our main goal is to emulate the massive national companies we’re doing work for,” West said. “[We] provide the level of service they’re expecting—even if they don’t realize that we’re a 23-employee company.”

Get back 1-2 days a week with Assignar

While Ultra Engineering kept meticulous records in the past, their process cost them time. Between their project manager spending days on logs, West completing payroll over two days, and the owner handwriting the schedule on a paper calendar, the team spent hours just capturing the details.

“With Assignar there’s a huge amount of time being saved not having to find information, find the forms, not having to wait for guys to come and turn everything in,“ West said. “We’re able to take all that raw data and just press a button and get the end result rather than do all the middleman steps of making it look good and organized.”

With Assignar, the Ultra team has taken their time back—time they can now spend on growing and improving the business. Newer trucks, more clients, and bigger projects are in their future.