2023 just started, and it already seems like a continuous stream of bad news.

Project costs have risen 20% to 40% in the past year, reports Construction Dive. With a low unemployment rate, rising interest rates and materials costs stagnating at ridiculously high prices, 2023 has a lot to overcome.

But the industry is optimistic. There’s still a construction work backlog that remained stable at 9.2 months in December. There’s no shortage of work—it’s just about maximizing what you have to get the work done.

With variables like labor, material costs, fuel, and equipment backlogs, you need a better handle on the things you can control.

Here’s how you can use data to increase your margins and efficiency to win more bids and maximize your margins—1% at a time.

Margins are too tight for mistakes

Success in the construction industry lies in the margin. A large project that’s on budget and on time can get off track with just one piece of heavy equipment failure.

It’s a cascading effect: the project stops while you search for a repair or replacement. According to Construction Dive, builders are still having trouble getting equipment delivered. You’ll likely wait longer than usual.

While you wait, fuel costs rise or the materials you need down the pipeline go up in price. The rest of the trades get pushed back, and your small margin gets eaten away by schedule delays and unexpected costs. With one unfortunate turn of events, you’ve gone from making a profit to being in the red.

This makes sense. The average margin in the commercial construction industry is 6%. While margins vary widely depending on where you fall in the industry’s food chain, chances are it’s on the tight end.

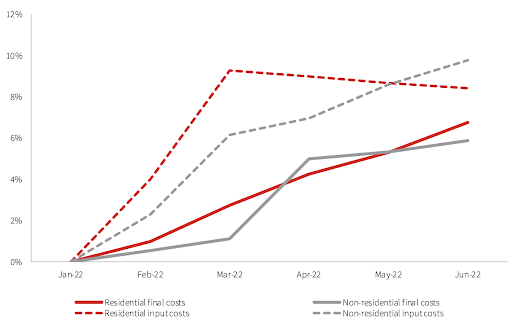

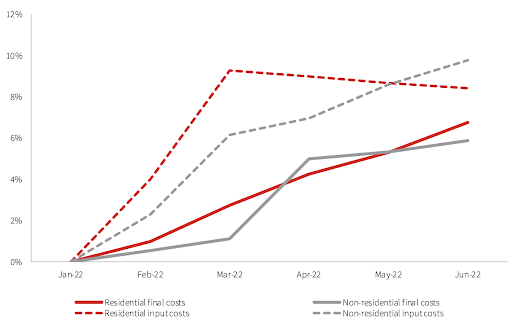

Plus, margins have gradually shrunk over the last few years, and the data backs it up. According to data from JLL, the final prices of nonresidential construction projects rose 6% between January and June 2022, but costs rose 10% during the same period.

Project input costs are outpacing final prices

Source: JLL

Why are construction margins taking a hit? It’s a combination of old problems and new ones. The labor shortage, rising material costs and variable fuel costs make it harder to quote projects. Between the time you bid on your project and when you start work, prices have risen. This volatility means there’s no room for mistakes. So what’s the answer?

Optimize operations with small improvements—and increase margins by 1% at a time.

Marcel Broekmaat, Chief Product Officer at Assignar, knows a complete operational overhaul isn’t feasible (or necessary) for construction firms to stay profitable.

“This is about marginal improvements that could make the difference between being profitable and taking a loss,” Broekmaat says.

With greater variability, construction firms need to get better at what they can control. To do that, you need sharp, accurate data.

Sharp data makes better margins

Planning is the backbone of the construction industry, and it’s hard to do when prices and labor are unpredictable. But that’s when planning becomes even more critical. When small mistakes add up quickly, you have less room for error.

It all comes down to data. Planning becomes infinitely easier when you have accurate data to pull from.

The good thing is, you’re not starting from scratch. Even if you’re still using analog methods (spreadsheets, whiteboards, pen and paper), you have data that informs how you plan work and bid on projects. Your years of experience mean you plan projects down to the dollar and, in normal circumstances, manage to get your actuals pretty close to your estimates.

But when margins are shrinking, accuracy is everything, and analog methods aren’t enough. Broekmaat points out that better data will get you closer to more accurate, confident planning.

“What if you could make [the data] sharper?” Broekmaat says. “What if it’s not just a one or two, but you have a decimal behind it as well that’s based on actual outputs on a daily basis per crew, per type of equipment?”

Over time, the data becomes a very good predictor of work—and it helps you make small improvements to protect and expand your margins.

Let’s take a look at how data can help improve your margins.

Bidding early on projects

When you have the data, you’re more confident that it’ll take three days to dig the trench, and your trencher will be available to move to another project on the fourth day. The farther out you can plan, the earlier you can bid on projects and fill up your backlog.

Lock-in material rates

As we mentioned above, material rates are volatile. When you’re confident in your plan, you can start purchasing materials early enough to lock in rates before they increase. Broekmaat agrees that this limits your risk.

“You’re curbing off the materials risk there because you know the scope. You can start purchasing the materials now or start looking for the best options,” he says.

Maximize resources

You can fight labor and equipment scarcity with data. When resources are scarce, you can’t afford to have equipment and workers sitting idle on a job site. Data ensures you know in advance what machines the project calls for, how many workers you need, the certifications required and how long it will take for each project.

“What if you could increase your level of confidence by measuring your average output and setting realistic expectations of when jobs can be done?” —Marcel Broekmaat, Assignar CPO

How to collect the most accurate data

Analog collection methods result in some data, but when you’re working with small margins, you can’t afford to get close. You need to be exact.

The first step? Start measuring.

Track hours and productivity

Track hours against daily productivity to see how much work is actually getting done on a day-to-day basis. While paper timesheets work, Broekmaat notes that digital options, like time tracking in Assignar, are easier and faster.

“To get the best results, you would have a purpose-built application that workers wouldn’t have to spend a lot of time in to track their hours,” Broekmaat says.

Digital time tracking helps you compare your budget against your completion rate, so you can see how long each step takes in real time. The more projects you track, the more reliable and informed your estimations will be. You can even anticipate and plan for delays like erratic weather.

Monitor equipment costs

Make the most out of every piece of equipment—and work toward keeping it from sitting idle—by tracking vital information. Construction software like Assignar can help. Use Digital Forms to track fuel consumption or Site Diary to monitor time in use.

Once you’ve captured enough historical data, Assignar can help recommend the right equipment for the job, taking into account certifications and availability.

Keep it all in one place

All of this information is useless if you don’t keep it in one easily accessible spot. Consolidate all of your data so it’s easy to access when you plan for future work.

Pulling up real-time information in platforms like Assignar makes it easy to spot when actuals are veering off budget, so you can address the problem sooner rather than later. You’ll also be able to make faster decisions with reporting and analytics tools easily at your disposal.

Sharpen your data with Assignar

The difference between making a profit and losing money could be 1%. Margins are becoming slimmer and slimmer, which means there’s less room for error when planning your projects. But with more accurate data and confidence in your projections, you can find success.