Australia’s first-ever construction hackathon – Constructathon 2019 was held in Sydney across two days on the 23rd and 24th of August. Constructathon was created to cultivate innovative solutions for the construction industry using technology. Industry leaders, tech heavy-weights and construction partners were essential to bringing the Constructathon to fruition. Specifically, Boral, Built, Roberts Pizzarotti, Mirvac, Stockland, Laing O’Rourke, Google, PCA, MATES in Construction, MBA and Cbus.

The Assignar team jumped at the opportunity to look at the construction industry through a new lens. As a software platform built for subcontractors, we were able to see the challenges of the industry as a whole. From a supplier to the general contractor level to the importance of work-life balance and employee wellbeing. As well as the interaction each plays with each other to deliver a project successfully whilst maintaining a culture of safety. We were joined by 60 other companies, all eager to contribute to this hivemind of seasoned technologists and industry experts to solve the real-world problems that reside in the industry.

The Challenge

Teams were challenged to provide solutions that circulated across 3 key themes:

– Work-life: How might we address mental health issues without stigma to help reduce suicide rates and encourage better work-life balance?

– Zero harm: How might we create safer working environments with zero fatalities and zero injuries?

– Efficient tech: How might we improve process by reducing paperwork transactions across the value chain?

Assignar was a part of the efficient tech stream and our team was a strong mix of experienced software developers and product designers. To assist in the scoping out of our ideas and to give us deep industry insight, Isabel Menton from Boral and Peter Whyte from Built were our industry experts and team coaches throughout the workshop process.

assist in the scoping out of our ideas and to give us deep industry insight, Isabel Menton from Boral and Peter Whyte from Built were our industry experts and team coaches throughout the workshop process.

During the first day, teams explored all the challenges that could be addressed in their assigned stream. With thorough discussions and research, the Assignar team decided to solve the efficient material delivery management in a work zone.

On average over 100+ suppliers deliver expensive materials to site each day. Given that the delivery area is often a constricted work zone, suppliers have a dedicated time slot for deliveries and each supplier needs to go in one after another at a limited capacity. In addition, variables needed to be accounted for. Such as, does the onsite crane need to be utilised to load the materials into the designated drop off area? Are the heavy vehicles delivering the materials in close proximity to other heavy equipment that could lead to safety concerns or incidents?

Given the number of variables that affect supplier deliveries, small delays create substantial damages. Delays disrupt schedules and because suppliers and subcontractors are all connected and dependant on each other to deliver certain parts of a project, a knock-on effect occurs. Consequently, suppliers and contractors lose copious amounts of time and money.

The Solution

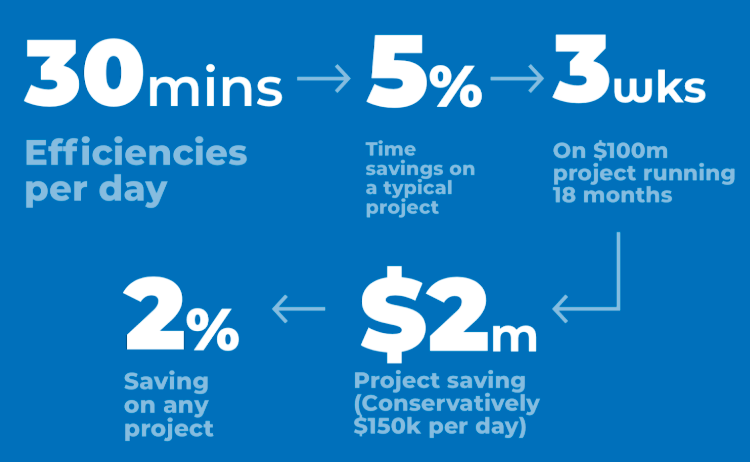

Upon weighing out these variables and challenges the Assignar team had one overall goal to generate tech-enabled efficiencies. Optimise supplier management by saving just 30 minutes a day in the work zone. Currently, $250,000 worth of materials is delivered onsite every day. By simply saving 30 minutes each day, contractors can save $150,000 a day.

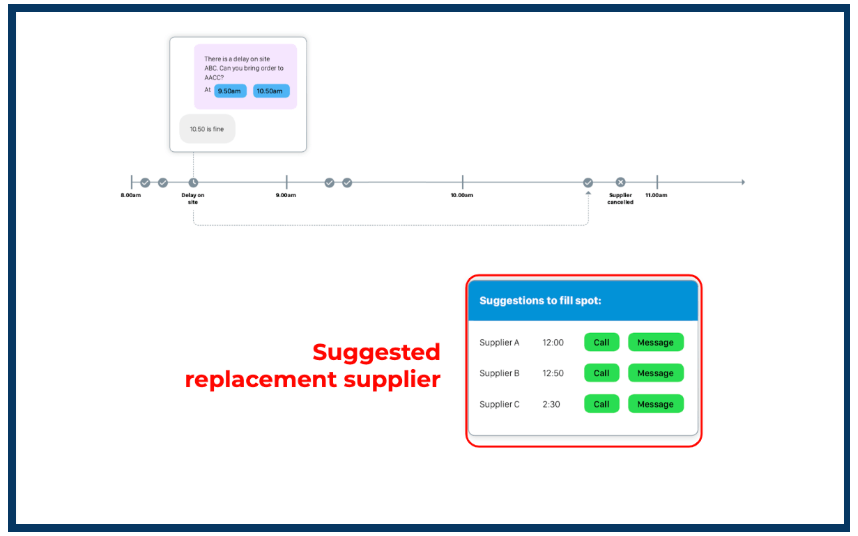

Assignar’s idea consisted of a platform that outlines a timeline of the supplier deliveries each day. Allowing the site manager to have greater control of supplier management and make data-driven decisions to optimise their time. Upon logging a delay or cancellation, a prompted message will suggest an alternative time for the supplier to re-enter the site or highlight alternative suppliers available to a timeslot. Afterwhich, they could be notified via call or message to secure the delivery time via the platform.

Through this solution, powerful data could be collated and actioned. Specifically,

– Track supplier deliveries

– Measure crane utilisation

– Identify bottlenecks

– Determine reliability

– Time efficiency

– GPS tracking

Day 2 – The pitch

On the second day, our CTO Marko Tomic had 5 minutes to pitch our solution and convey the power of data to deliver projects on time and save money wasted on delays. He was supported by Lisa Chi who provided expert advice on how to pitch and how to put all our passion into a very convincing slide deck. A panel of 6 judges weighed out the pitches and the winner of the Contructathon was OkayMate and their solution to provide zero harm and Mojo with their wellness app. Both teams will proceed to the incubator phase where they have 6 weeks to further validate their ideas, research and explore whether a minimal viable product is a possibility for their solution.

Lessons learnt

We had different experience levels from an industry, engineering and hackathon perspective in our team. This was the first hackathon for our Product Designer Joyce Sueko. Joyce speaks of her experience as, “the most intense 2 days I ever had, full of learnings. We were tasked to understand the most challenging pain points from the construction industry and as a group try to solve some inefficiencies on this very complex industry in 2 days. This sounds challenging but not impossible!

For me this experience was amazing, I could never get all these rich insights by myself in such a short time, compared to what I had learned in those 2 days and at the site visit. Great memories from my first hackathon, and feeling thankful for this opportunity as it made me aware of where I can improve on myself.”

As a software platform for subcontractors, our team were well-versed in tech-enabled efficiencies. But what was a big eye-opener for the team was how big a role mental health and creating a safe environment has to combat the stigma of macho culture, the long hours, physically and mentally demanding work construction workers do and the lack of job security.

Every two days in Australia, a construction worker takes their own life.

Often we can get bogged down in processes, the granularity of workflows and operations and forget the human factor of our work. This reminder of the harsh reality of the industry we support really hit home for our team. At the end of the day, the more we learn about the industry, the more we can support their business and hopefully ease the burdens that reside operationally in their work lives. With this small peace of mind, we hope that the industry can achieve what has been so hard for so long – work-life balance.